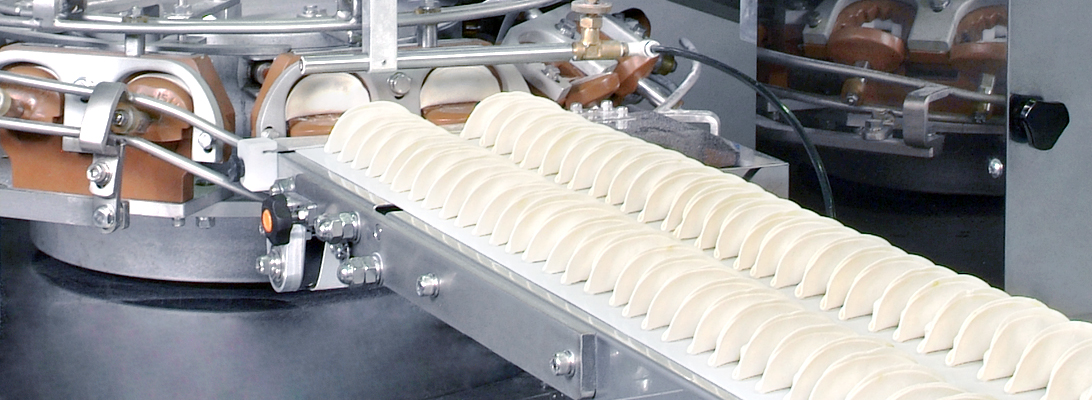

We aim to bring the Quality of Handmade Gyoza to Automation.

We carefully craft not just the taste, but also the shape and texture. Our original technology enables us to replicate the delicacy of hand-made gyoza, making our machine-made gyozas both efficient and true to tradition.

We focus exclusively on gyoza dumpling machines, ensuring high quality and reliable service from our gyoza experts.

Development and Design

We create original designs down to the component level, faithfully reproducing the delicate hand pressure to make gyoza.

Toa Industry's gyoza machines enhance both taste and productivity. We work closely with clients to meet requirements for flavor, texture, production speed, and labor-saving. From prototype creation to operational verification, we provide a streamlined process for efficient equipment implementation.

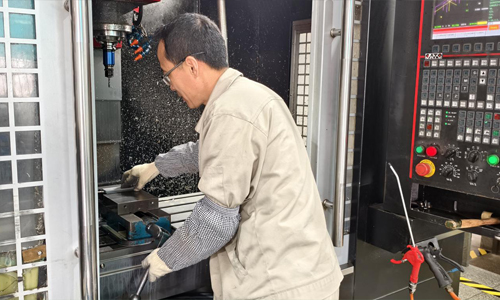

Manufacture

We manufacture most of the key components in-house, ensuring quality and continuing supply of parts.

Just as gyoza tastes vary from shop to shop, no two Toa Industry gyoza machines are the same. Our specialized division creates machines that reflect each customer's brand. With in-house processing and skilled assembly, we ensure efficient production through a streamlined manufacturing process.

Quality Control

A thorough inspection system that achieves a weight tolerance of less than 1 gram for each gyoza.

Toa Industry's gyoza machines maintain precise weight tolerance down to the gram. We conduct quality checks at every stage—design, parts processing, assembly, and shipment—to ensure flawless products. For outsourced parts, we apply our own quality control standards to uphold the Toa brand's high quality.

After Sales Service

With a comprehensive maintenance system in place, we minimize operational downtime.

Toa Industry’s maintenance department aims to minimize downtime. We store all specification data and use an integrated system for quick recovery during failures. We also offer support for machine upgrades, equipment consultations, and maintenance training at our factory.

Our Gyoza Machines are HACCP compliant.

With years of experience in food manufacturing, Toa Industry’s gyoza machines incorporate field feedback from the design stage. We use hygienic materials like stainless steel and antimicrobial resin for large machines and a disassembly structure that simplifies maintenance. Food-zone components are easy to disassemble, clean, and reassemble, ensuring high hygiene standards. Our extensive delivery record to HACCP-compliant factories is a testament to our reliability.

Toa Industry's integrated system accelerates your company's PDCA cycle.

Toa Industry manages everything from development to after-sales maintenance with an integrated system. We support your site improvements and drive the PDCA cycle. Our service goes beyond gyoza machines, offering both the machinery and the technical know-how for unique, synergistic improvements that only Toa Industry can provide.