Automatic dumpling machine TX-16-DL full set of equipment

Industry first to achieve HACCP standard machine

Only 5 minutes, easy to unload cleaning to strict sanitary specifications

Only 5 minutes, easy to unload cleaning to strict sanitary specifications

- 10,000 / hour

- Corresponds to HACCP

- 200V/380V voltage

- Full automatic

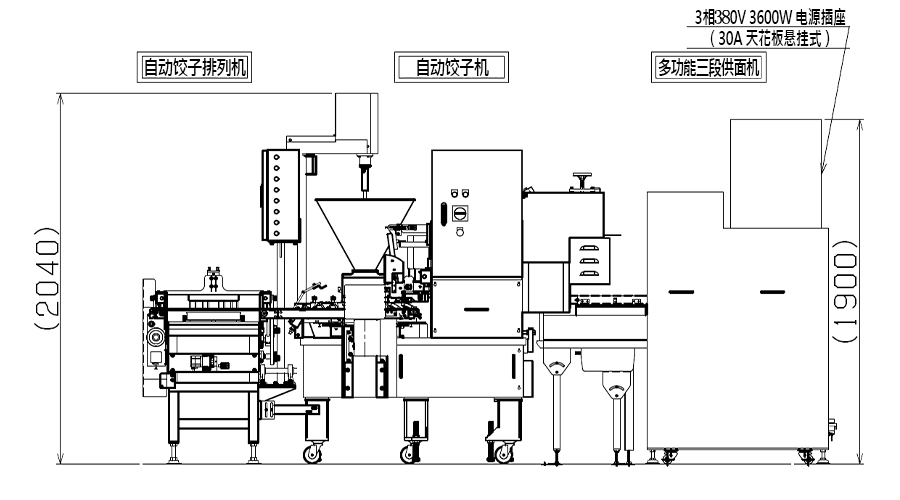

Automatic dumpling machine TX-16-DL Full set of equipment type [Multi-functional three-stage flour feeder products]

TX-16-DL Complete equipment type [Multi-functional three-stage flour feeder equipment] Main dimensional drawing

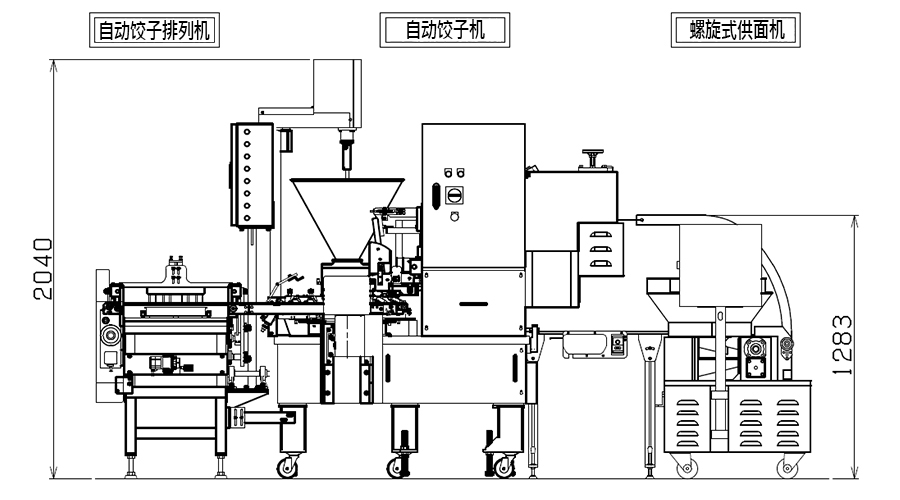

TX-16-DL Complete equipment type [Screw feeder equipment]

Automatic dumpling machine TX-16-DL Complete equipment type [Screw feeder equipment] Main dimensional drawing

Item Information

Item Details

This is a full setup of Fully Automated Gyoza

Machine / Dumpling Machine TX-16-DL with auto dough sheeter and auto tray

loader, enabling complete automation order-made to your requirements.

This machine has a production capacity of 10,000 dumplings per hour

enabled by completely automating the process of dough sheeting, gyoza

dumpling formation and loading of gyozas onto trays. This will provide

utmost convenience to customers who are looking for further automation

and increased efficiency.

There are 2 types of dough sheeters; 1) multi-purpose 3 tier dough sheeter which has pursued better, tastier dough by introducing innovative technology such as the process of recycling cutoff dough etc, and 2) screw-type dough sheeter which is our standard model.

There are 2 types of dough sheeters; 1) multi-purpose 3 tier dough sheeter which has pursued better, tastier dough by introducing innovative technology such as the process of recycling cutoff dough etc, and 2) screw-type dough sheeter which is our standard model.

Characteristics:

- Designed to the customer's specification of gyoza dumpling size and fillings quantity etc.

- Automated production of gyoza dumpling wrappers

- The cutoff dough sheet is returned to the dough sheeter for recycling

- Auto-alignment into 6 to 12 rows according to the nets or conveyors used by the customer.

- Auto-loading onto the vats or trays used by the customer.

Specifications

| Capacity | 10,000 pieces per hour |

|---|---|

| Molds Qty | 16 |

| Discharge Conveyor | Auto Alignment Type |

| Dough Roller Width | 230mm |

| Dispatch of Hyper hydrated dough | Air Shower Method |

| Discharge Method of Product | Alignment on the conveyor (Chosen from 6,9 or 12 rows) |

| Air Supply | On-site machine must used. This machine does not come with air supply. |

| Main Machine Measurements | 3310mm×1743mm×1665mm |

| Electrical Power | Main Machine Drive 3 Phase 200V/380V 0.750kW |

| Screw Drive | 3 Phase 200V/380V 0.090kW |

| Dough Sheeter Drive | 3 Phase 200V/380V 3,000kW (1 Stage 1,500kW, 2 Stage 1,500kW) |

| Machine Weight | 1250kg |

Our Videos

TX-16-DL with full options main features

2 types of dough sheeters to choose from.

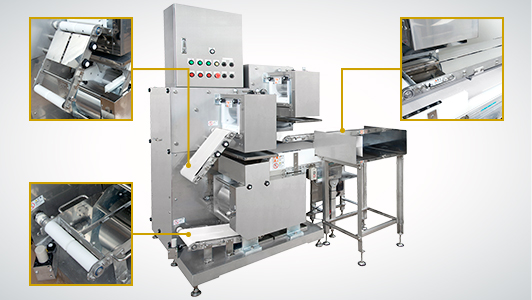

[Multi-functional & High Quality ] Multi-purpose 3 Tier Dough Sheeter ※Patent pending

Great texture and taste is realized

by placing the recycled dough on the inner side of the dough sheet

In pursuit of better tasting dough, we have

introduced a new model for the dough sheeter with dough recycling

function. This multi-purpose 3 tier dough sheeter with our original

dough sheeting mechanism will place the new dough on the outer side of

the dough sheet, and by efficiently recycling the recycled dough, the

fresh taste and quality of the dough is maintained till the end of the

lot.[Standard Model ] Screw-Type Dough Sheeter

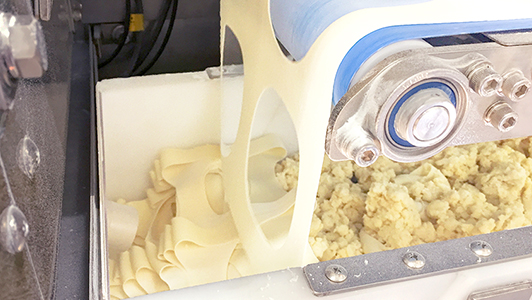

Makes a fine dough sheet in a short time

and recycles the remaining skin automatically.

Prepares a fine dough sheet with patented twin

screws in a short time. It will simplify the cumbersome process of the

dough sheeting, and will also automatically recycles cutoff skin,

thereby reducing loss and realizing efficient and labor saving method.

Please use in conjunction with our fully automated gyoza machine / dumpling machine TX-16-DL.We have extensive optional equipment to support mass production

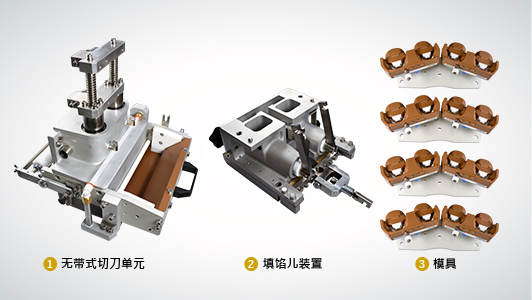

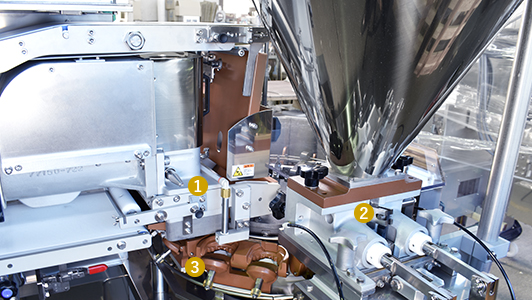

Replacement Units

By replacing the units,

Different sized gyoza dumplings can be produced with ease.

By replacing the units made up of a beltless cutter unit, fillings

loader unit and pallet molds, it is possible to produce different sized

dumplings. It supports a wide range of sizes from 15 g to 30 g. As you

become familiar with the replacement work, you can change parts in about

5 minutes, thus contributing greatly to improvement of production

efficiency and sanitation management.Sub Dough Sheeter

A Sub Dough Sheeter with a large handle

with which the thickness of the dough sheet can be easily adjusted.

During the process of thinning of the dough, if the dough sheet is too

thick when passed through the roller, the dough quality reduces and it

will affect the taste of the dumplings. Additionally, it results in the

overload of the dough sheeter, and is not recommended for mass

production over a long period.By introducing the Sub Dough Sheeter and performing the thinning process in 2 steps, it avoids the above mentioned problems, thus producing fine ideal wrappers for your dumplings.

Automated Loader

This machine covers both mass-production and labor-saving.

An automated loader that eases the last stage of production.

This is an automated tray loader that reduces time and labor at the

production line. By attaching this machine to the fully automated gyoza

machines / dumpling machines, the product is loaded onto the trays and

vats automatically. Furthermore, by attaching a tray loader as well, the

supply of trays too can be automated.Specifications

| Capacity | 9,000-10,000 pieces per hour(under the condition of Gyoza weight, filling material and shape, etc.) |

|---|---|

| Molds Qty | 16 |

| Discharge Conveyor | Auto Alignment Type |

| Dough Roller Width | 230mm |

| Dispatch of Hyper hydrated dough | Air Shower Method |

| Discharge Method of Product | Alignment on the conveyor (Chosen from 6,9 or 12 rows) |

| Air Supply | On-site machine must used. This machine does not come with air supply. |

| Machine Dimensions(Length×Width×Height) | 3775mm×1945mm×2040mm(Multi-Purpose 3 Tier Dough Sheeter) 3480mm×1945mm×2040mm(Screw-Type Dough Sheeter) |

| Total power consumption | 5.3kW(Multi-Purpose 3 Tier Dough Sheeter)/5.1kW(Screw-Type Dough Sheeter) |

| Machine Weight | 1900 kg (Multi-Purpose 3 Tier Dough Sheeter)/1600kg(Screw-Type Dough Sheeter) |

Next success story is yours!

Listen to what our customers have to say about us.